Des fixations de très haut niveau

Faites confiance en un procédé de production qui vous permet de tirer davantage de profits : sur nos lignes de production, nous combinons le roulage-pliage à des procédés de laminage et obtenons ainsi des résultats optimaux. Nous développons des solutions qui remplacent de manière rentable des éléments issus d’autres procédés de production, par exemple des pièces embouties, des pièces decolletées ou des sections tubulaires.

Laissez-vous convaincre par notre large assortiment. Nous proposons tout ce dont vous avez besoin pour une production sûre et efficace : des goupilles, des douilles de serrage, des goupilles spiralées, des bagues de châssis, des entretoises, des limiteurs de compression et des goupilles élastiques pour l’automobile.

Vous avez des souhaits particuliers ? Aucun problème pour nous : avec vous, nous cherchons une solution afin d’améliorer vos processus. Nos ingénieurs élaborent ensuite des produits sur mesure qui vous permettent de produire de manière plus fiable, plus économique et en consommant moins de ressources.

SPRING TENSION PINS

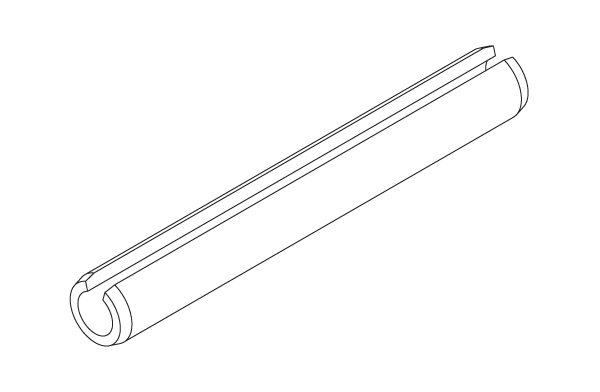

Slotted spring pins

ISO 8752 (heavy duty) | ISO 13337 (light duty)

ASME B18.8.2 | ASME B18.8.4M

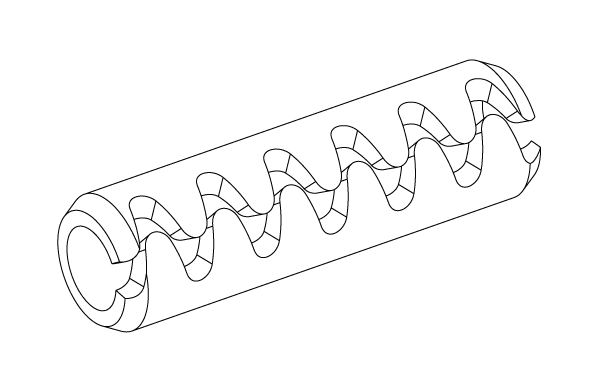

Coiled spring pins

ISO 8748 (heavy duty) | ISO 8750 (standard duty) | ISO 8751 (light duty)

ASME B18.8.2 | ASME B18.8.3M (all duties)

CUSTOM-ENGINEERED PINS

Specific forms of slots prevent pins from tangling during automatic feeding processes on assembly lines, or during coating operations made on the pins themselves.

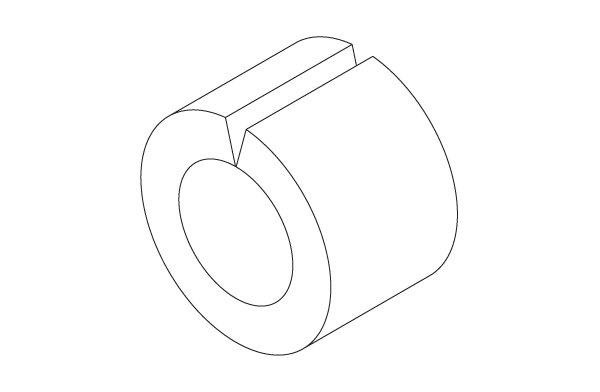

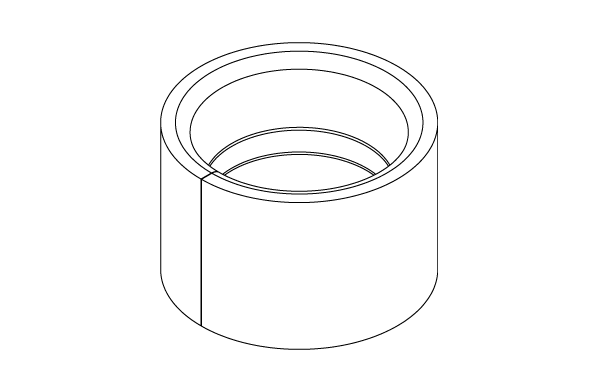

TENSION BUSHINGS

Any shaft movement in a bore induces friction wear of the shaft and / or the bore. In order to avoid this major inconvenience, it is therefore essential to insert an intermediary part, made of more resistant material, between the two relatively moving parts. Tension bushings, easily inserted and withdrawn, are the rational and economical solution to solve this problem.

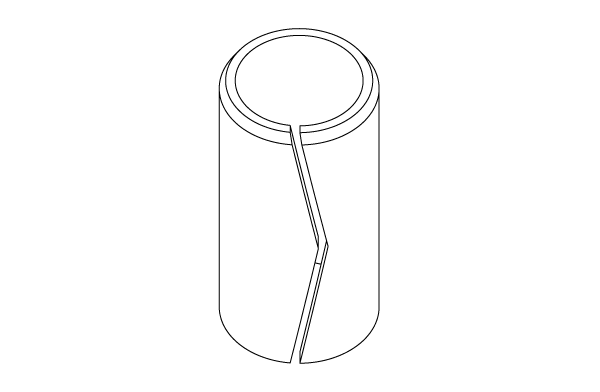

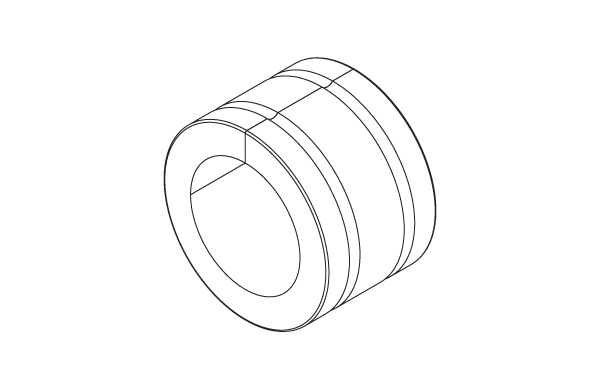

GROUND HOLLOW DOWELS & GRINDED PINS

Guidance and relative positioning of two parts. | Slot enables to compensate some misalignment or bore faults. | Grinding matches the specific requirements of precise assemblies.

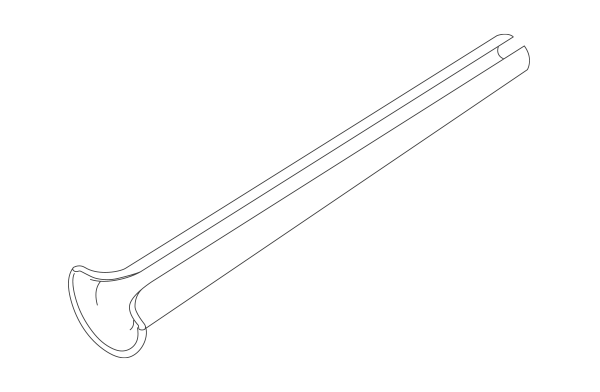

SPINDLE

Axles for rollers, for pulleys, for hinges, for caps, and all kinds of other swiveling assemblies. Quick fitting by bushing operation. Reduced mass thanks to hollow body. The spindle elasticity compensates for some clearance / free play caused by wear. During rotation, the sunken edges of the slot do not damage the bore.

SPACERS

Spacers are used in special processes to assure a correct and fixed distance between two connected modules. Moreover the spacer absorbs the tightening force of the screw.

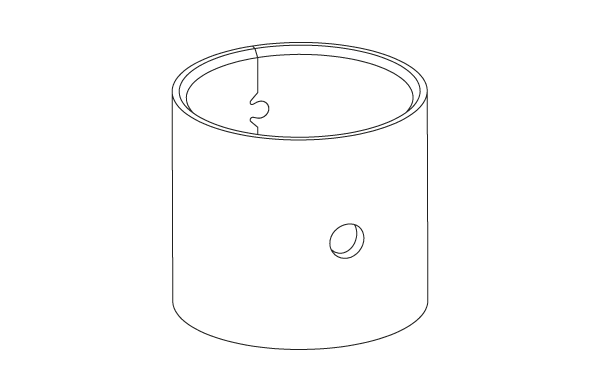

COMPRESSION LIMITER

These products are designed in order to strengthen plastic, wooden and rubber bores. Of various shapes, and easily fitted in position thanks to their slot, these parts prove their functional utility in all kinds of assemblies where mechanical forces are exerted on components made of tender / soft materials.

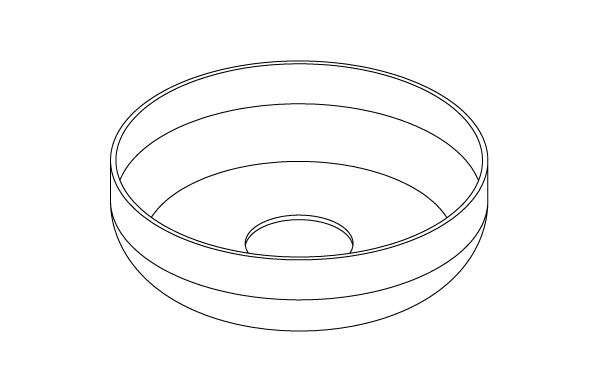

EXPANSIBLE AND CUP PLUGS

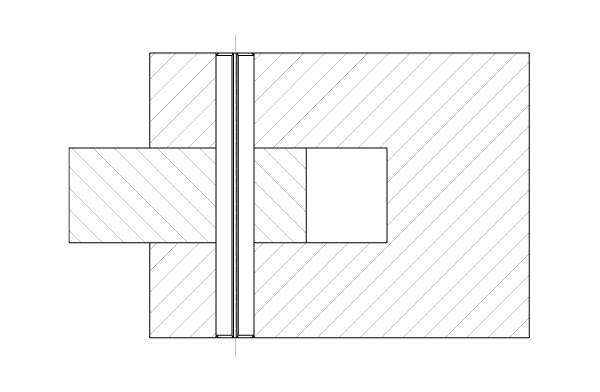

CHASSIS BUSHINGS

A bushing with a defined oval shape and a clinched connection which gets welded in the customer’s assembly. The elliptical shape will draw back to round due to the weld distortion. Used in: Twist beam rear axle, multilink axle, transverse, control arm and more. Design: oval or round.

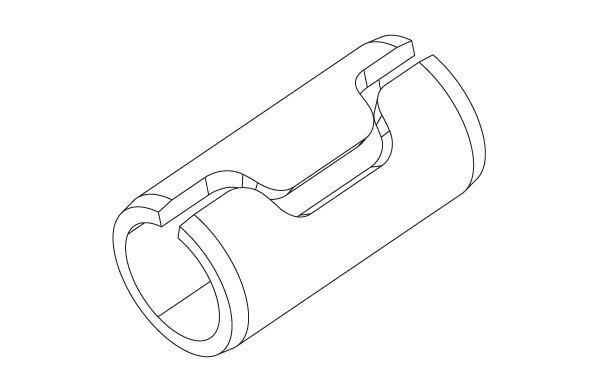

SHOCK ABSORBER SLEEVES / WELD EYE RINGS

Designed to accomodate the shock-absorber mounting. Solution: Conical shapes, achievable by means of cold extrusion or by using profiled strip metal. Use of profiled strip steel makes other geometrical shapes and applications possible. Various types of slot can be produced.

EXPRESS NAILS

The design features of our pin have enabled to increase its already excellent rigidity by another 20%.

Material fibre orientation is now uninterrupted and no projecting interlocks.